The Northeast kingdom railroad

Freight Car Repair Facility

When looking for on-line industries to add to our layouts, we usually have some criteria in mind. For some layouts, there are certain must-have industries that reflect the railroad being modeled. For instance, a coal hauling railroad such as the Clinchfield will need to have coal mines and loading facilities, while a paper hauling railroad like the Maine Central will need paper mills and pulpwood loading facilities. For additional industries, the choices usually come down to personal favorites as well as industries that will support some of the rolling stock we have accumulated. We may not be able to find a brewery along our prototype’s mainline, but if the building looks good and we like beer, we’ll find someplace on the layout for it, along with that string of insulated boxcars and grain hoppers we’ve already purchased.

For something different that can receive virtually any type of freight car, a freight car repair facility is fairly easy to model and has lots of operational potential.

April 2002

NER Coupler

This is an article I wrote for the NER Coupler. It is information about a freight car repair facility, an ideal model railroad industry. This article was published in the April 2002 issue of the Coupler.

When modeling this facility, don’t forget the extra detailing. A sign on the building and nearby will help identify the industry. There should be some figures around and inside the building working. Some tools and machinery may be viewable inside the building, depending on how you place the building on your layout. Exterior lighting, an electrical meter, power poles and lines, cars and trucks in the lot and spare new and used freight car parts will help round out the detailing.

Traveling along Rt. 3, I noticed a few flat bed trucks carrying wheel sets destined for this facility. This would make an interesting detail on a nearby road or in the parking lot, using a Lonestar flatbed trailer and some Tichy wheel sets.

So, if you have a few freight cars that are only serving as run through cars right now because there is no plausible destination for them on your railroad, consider adding a freight car repair facility to your layout. A little bit of trackwork and an easy to put together kit shouldn’t take too long to model. Adding a dedicated locomotive is optional, but could create an operational position. The facility as-is would look appropriate for any layout set in the past 30 years or so. Backdating the building a bit, perhaps using brick, should make it work for layouts set in an earlier era.

The North Stratford Freight Car Repair Facility handles light freight car repairs for other railroads or private shippers that do not have their own facilities or prefer to outsource this work to a business specializing in the needed repairs. The facility is made up of a large shop building with 2 tracks that run through it. Extra tracks adjacent to the building hold cars awaiting their turn in the shop. A single switch off the mainline and a runaround track serve the facility. A small parking area handles the employee’s cars as well as shipments of parts in tractor trailers.

The inspiration for this came from one such company located in North Stratford, New Hampshire, along the right of way of the New Hampshire Central. This track used to be part of the Maine Central’s Beecher Falls branch, and then later was operated by the North Stratford Railroad (NSRR), primarily hauling furniture for the Ethan Allen company.

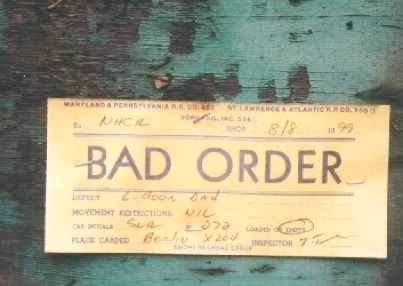

A few miles west of the facility, the New Hampshire Central interchanges with the St. Lawrence and Atlantic (ex-GT) in North Stratford, along the line that runs between Montreal, QC and Portland, ME. When I visited, the small yard in North Stratford had a string of bad order freight cars awaiting their trip to the repair facility. Each car had a Bad Order card attached to the tack board indicating what the problem was and routing information specifying the New Hampshire Central as the destination.

The shop building itself is right out of the Pikestuff catalog, a large metal sheathed structure with a few windows and large roll up doors for each track. The building is painted a light tan color with white doors on a concrete foundation, but almost any color would work. A model can be constructed to fit your available space and should be large enough to hold at least a couple of cars. The North Stratford building has the tracks travel through the building and out the other side for about 3 car lengths. This can be altered if needed to meet your layout requirements. An office area can be modeled as an add-on to the side of the building if desired, but the prototype has no actual separate office building.

A New Hampshire Central GE 44-Ton locomotive is on-site to handle shuttling the cars around for the repair crews as well as making the trips to the interchange track. This locomotive is ex-MEC and ex-NSRR, so it is already familiar to these rails (See my NSRC page). It has been repainted into a new yellow paint scheme with black lettering. This is an opportunity to paint up that unique locomotive you picked up that doesn’t quite fit your prototype. This leads to more operational potential. An operator can be stationed here to receive and set out cars as well as handle in plant switching moves.

The opportunity to receive many types of freight cars from a variety of railroads is appealing. On my visit, I did notice a couple of blocks of cars for a single railroad, indicating perhaps contract work to overhaul a series of cars for another railroad. Also on hand was some cars lettered “LVRC”, which is the Lamoille Valley railroad. This line no longer operates, but the reporting marks are used by a freight car leasing company. They must have contracted this work to keep their cars in working order. Other cars were from the interchange railroad, the St. Lawrence & Atlantic as well as a string of green covered hoppers for BRIX lettered Incobrasa Industries.

Web page written and maintained by Mike McNamara

>> Back To Articles main page