The Northeast kingdom railroad

MER Trip to the Homasote Plant

At the MER Fall Convention, Cherry Hill Depot, the prototype tour on Friday afternoon (Oct. 4, 2002) was a visit to the Homasote Company in West Trenton, NJ. As most model railroaders know, Homasote is a 4' x 8' building product made out of compressed newsprint. We use it on our layouts for roadbed and under large areas like yards and towns. Homasote has other uses of course, and our tour showed us how the product is made and what some of those other uses are.

Getting to the plant itself was a little bit exciting. We left the hotel right on time, but soon we were pulling over to the side of the road on I-295. Our bus's radiator belt gave out and we were overheating. Despite the driver's best attempt to get us there at 5mph driving on the shoulder, a call for a replacement bus was made. After a few minutes, we transferred to the other bus and proceeded without further incident.

Nov/Dec 2002

MER Local

This is an article I wrote for the MER Local. It is a report on a prototype tour to the Homasote plant in West Trenton, NJ. This tour was part of the MER's Fall 2002 Convention, Cherry Hill Depot, hosted by the New Jersey Division. This article was published in the November/December 2002 issue of the Local.

We all had a great time, both those taking the tour and those giving it. All in all, this was a terrific prototype tour. It is just the kind of unique activity one can find at each Regional Convention. Whenever you attend a Regional Meet, always consider participating in the prototype tour. It gives you a chance to see and do things that otherwise are not available to you. This is just one more way that MER membership and participation in the Convention benefits you directly.

Now the next step is to build a model of the Homasote plant for my layout. Although the product is made only in the West Trenton facility, a little modeler’s license could be used to open a second plant in northern Vermont, along the mainline of my model railroad!

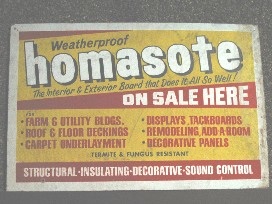

First we received some background on the company itself. The company was founded in 1909 as the Agasote Millboard Company and is the oldest US manufacturer of building products made from recycled waste. The company used a secret process purchased in England to produce a high density fiberboard. Early on, the product was used in roof panels of railroad cars and automobiles. In 1916, the Homasote product was developed and it was used in all sorts of building applications. The company changed its name to Homasote Company in 1936. Today, Homasote is a $30 million dollar public company (stock symbol HMTC) that produces products for sound-deadening in walls and floors, fabric covered office partitions, Homex concrete expansion joints and customized packaging solutions. They also produce, of course, standard 4' x 8' sheets for model railroaders (and others)!

Arriving at the plant, we were greeted by a Homasote salesman who would be conducting the tour. A couple of surprises were in order. First, we were told that the president of the company would be joining us on the tour, a real treat as he was thoroughly knowledgeable on his companies operations. Also, Homasote had prepared a few samples of their products and a company hat for us to take home. A nice touch!

Arriving at the plant, we were greeted by a Homasote salesman who would be conducting the tour. A couple of surprises were in order. First, we were told that the president of the company would be joining us on the tour, a real treat as he was thoroughly knowledgeable on his companies operations. Also, Homasote had prepared a few samples of their products and a company hat for us to take home. A nice touch!

Our tour started at the beginning of the manufacturing process where raw materials are received. A sheet of Homasote starts out with recycled newspapers. In fact, area trash trucks bring curbside recycling directly into the Homasote plant from a 3 county area in New Jersey. When demand is higher, recycled paper is purchased from other areas as well. The trucks dump their loads right onto the floor. Workers then hand screen the loads for cardboard and other debris not suitable for the Homasote process. Interesting anecdotes were given about some of the items found while screening the paper. All cardboard is collected and sold to other companies as the fiber in cardboard is too large to use.

After this separating of materials is completed, the newsprint papers are loaded into a large vat that looks very much like a large kitchen blender (very large!). It is twenty feet deep and has 6 foot blades at the bottom. The paper is loaded in and hot water is added. The blades rotate, breaking down the paper into fibers small enough to fit through the 3/16" exit holes at the bottom of the vat. This process is called repulping and the mixture produced is 98% water and only 2% newspaper. These exit holes lead to pipes that remove any non-fiber debris (dirt, rocks, glass, etc.). Next, a copper chemical and paraffin wax are added to the mixture to finish the ingredients. Only these four basic ingredients are needed to produce Homasote. The gray tint of Homasote is a result of remaining newsprint ink

We walked to the molding area next, where this paper fiber liquid is poured into molds measuring 8' x 12'. Most of the excess water is pressed out of the mold and this water is recycled and used again. The semi-stiff board travels on rollers to the next step. Here, each board is placed between large flat panels to remove more water and compress the board down to its half inch thickness. Each board is then loaded into a large oven for hardening and removing all but 2% of the remaining moisture. Homasote has two ovens, one older gas unit, and a newer electric unit. These are approximately 16' x 275' in size and each board slowly travels on rollers through the unit for about 2 1/2 hours until completely finished.

Leaving the ovens, the boards are stacked into neat piles, many feet tall. These stacks are then wheeled over to the large cutting saws which cut the boards down to the size needed, usually 4' x 8'. As you may guess if you've ever cut Homasote with a saw, they employ powerful dust collection machinery in this area of the mill!

This process is used not only for standard 1/2" thick boards but also other thicknesses as well. The molds, presses, ovens and saws can all be modified to handle different thicknesses, drying times and sizes.

From here the product is ready for shipment. Most is shipped by truck although a rail siding is available and occasionally used. Customers include California Roadbed, makers of the Homa-Bed product. They purchase a couple of truck loads each year for their product, which receives additional milling to reduce the thickness, bevel the edges and allow curving.

Not all of the product is shipped right out, however. The other half of the company, Pak-Line, produces custom cut pieces ordered by a wide variety of customers. This ranges from packaging material for auto parts, glass, explosives and appliances to a line of designer children’s furniture.

On the day we visited, the plant was down for regularly scheduled maintenance. The process used along with the age of the equipment requires extensive cleaning and maintenance. The president indicated that a 40 person crew is used to perform these tasks. With the assembly line down, we were not able to see the product being made, but it did allow for a much quieter visit. Production is run in 3 shifts, 24 hours a day, generally from midnight Sunday through Friday afternoon. Saturday is used for maintenance. When demand is higher a 12 day non-stop schedule is in place, followed by the maintenance.

More information is available on-line at the company's web site, www.homasote.com. Here you will also find a dealer locator that allows you to enter your zip code or state and find nearby businesses that sell Homasote. They give you names, numbers and miles from your area! In general, lumber yards and building supply companies will carry Homasote or can order it for you. Occasionally you can also find the product in Home Depot and Lowe’s.

Web page written and maintained by Mike McNamara

>> Back To Articles main page